Microfiltration Membranes Lead the Way in Water Filtration

Microfiltration Membranes Lead the Way in Water Filtration

May 14, 2025

Like all the smart devices we use daily, water filtration technologies are constantly evolving. For water treatment professionals prioritizing precision and efficiency, hollow-fiber microfiltration membranes are revolutionizing the way industries and municipalities treat water.

Versatile, efficient, and adaptable microfiltration (MF) membranes have set a new standard for high-quality filtration. MF modules are the core of the modern water treatment systems from Aria Filtra®. Many of our trusted membranes are NSF / ANSI 61 certified for compliance in drinking water applications. Additionally, our proven systems have a small footprint, are modular, and are fully automated.

Continue reading to learn more about the intricacies of hollow-fiber microfiltration membranes, their applications, and how Aria Filtra is a leader in delivering high-quality water solutions for diverse applications.

Understanding Microfiltration

Microfiltration is a filtration process that removes particles, bacteria, and other contaminants from water using membranes with pore sizes typically between 0.1 and 10 microns. Unlike conventional filtration methods, microfiltration provides an advanced level of separation, making it highly effective for applications requiring high-quality water.

While ultrafiltration membranes can filter out viruses and small organic molecules, microfiltration membranes excel at removing larger particles like bacteria, colloidal silica, and suspended solids. This makes them ideal for applications where maintaining water clarity and purity is essential without removing dissolved ions or salts.

How Microfilter Membranes Work

As water is forced through the membrane, contaminants larger than the pore size are physically blocked, while clean water passes through. Depending on the design, the process can either be:

- Inside-out flow, where water enters the hollow fiber's core and exits through the walls, leaving contaminants trapped inside.

- Outside-in flow, where water flows around the fiber's exterior, with filtered water collected inside the hollow core.

This dual operational capability allows manufacturers to customize microfiltration systems based on specific needs, ensuring optimal performance for various applications.

The Role of Hollow-Fiber Membranes

The development of the hollow-fiber membrane is one of the most significant innovations in microfiltration technology. Hollow-fiber membranes comprise thousands of long, thin fibers with a semi-permeable wall. Water flows through the hollow cores of these fibers, while contaminants are trapped either inside or on the surface, depending on the filtration design.

Key Characteristics of Hollow-Fiber Membranes:

- High surface area: The compact arrangement of fibers provides an extensive surface area for filtration, ensuring maximum efficiency.

- Flexibility: Their modular design allows for scalability, making them suitable for small-scale residential systems and large industrial setups.

- Durability: Made from robust materials like polysulfone or polyvinylidene fluoride (PVDF), hollow-fiber membranes resist oxidizing agents and can withstand high pressures and harsh conditions.

Advantages of Microfiltration Membranes

1. High Filtration Precision

Microfiltration membranes are designed to remove particles down to 0.1 microns, ensuring the effective elimination of most bacteria, suspended solids, and turbidity.

2. Energy Efficiency

Compared to reverse osmosis systems, microfiltration operates at lower pressures, significantly reducing energy consumption. This makes it a cost-effective solution for small-scale and industrial applications.

3. Operational Versatility

The modular nature of hollow-fiber membranes allows for easy scalability and customization. Systems can be expanded or reconfigured to meet changing water quality or production demands.

4. Durability and Longevity

Constructed from high-performance materials, microfiltration membranes are built to withstand rigorous operational conditions, ensuring long service life and minimal maintenance costs.

5. Sustainability

Microfiltration contributes to sustainable water management by enabling water reuse and reducing waste. Its ability to operate efficiently with minimal chemical additives further enhances its environmental profile.

Microfiltration Membrane Applications

Hollow-fiber filtration is particularly effective in applications such as industrial water treatment, municipal water treatment, food and beverage production, and mining and metals. Its ability to deliver consistent results while maintaining operational flexibility makes it a preferred choice for industries requiring high-performance water filtration solutions.

1. Industrial Water Treatment

In industrial settings, microfiltration membranes are vital for removing suspended solids, bacteria, and oil droplets from process water. Additional applications include:

- Incoming water

- Boiler feed water or cooling tower make-up

- Injection water

- Cooling tower blowdown

- Coal seam/bed methane

- Discharge water

2. Food and Beverage Industry

Microfiltration membranes are indispensable for optimizing environmental and economic efficiencies in the food and beverage sector. From enhancing the cleanliness of discharged water to limiting dependency on outside water, microfiltration helps food and beverage companies reduce labor and recycle water.

3. Municipal Water Treatment

Municipalities use microfiltration as a primary barrier against microbial contamination and other organic and colloidal contaminants. Aria Filtra solutions treat more than one billion gallons of water for thousands of municipalities around the world every day. We take pride in providing municipal customers like Castle Rock Water with reliable membrane filtration systems.

Castle Rock Water provides drinking water to more than 63,000 residents in the Town of Castle Rock, Colorado. It sought to transition from its reliance on non-renewable water sources of deep groundwater wells to a renewable water supply. Aria FLEX™ performed exceptionally well for Castle Rock’s Plum Creek Water Purification Facility. The system’s robust membranes allowed them to treat water from virtually any source, which was crucial to Castle Rock Water’s success.

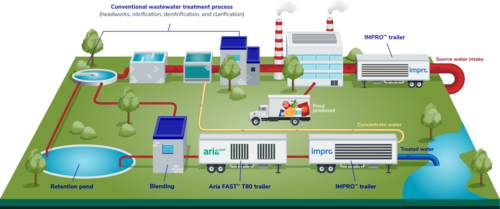

4. Wastewater Reclamation

Microfiltration membranes play a crucial role in wastewater treatment, where they are used to remove solids and pathogens before further treatment processes. Their high efficiency in reclaiming water for industrial reuse or irrigation contributes to sustainable water management practices.

When Egypt enforced new wastewater discharge bans, Egypt's largest polyethylene producer was determined to implement zero-liquid discharge (ZLD). They chose the Aria FLEX membrane filtration system for pretreatment for its ability to handle their challenging feed water—a mix of treated effluent and Nile River water.

Future Trends in Hollow-Fiber Filtration

As industries continue to demand higher quality and more efficient water treatment technologies, hollow-fiber filtration systems are evolving to meet these challenges. Emerging trends include:

- Nanotechnology integration: Incorporating nanomaterials into membrane structures improves filtration efficiency and fouling resistance.

- Smart monitoring systems: Using sensors to provide real-time data on membrane performance and maintenance needs, Aria SMARTBOX™ helps treatment plant operators manage systems more effectively by giving them a powerful set of tools, including intuitive dashboards, historic system trends, automatic reports, and real-time alerts. With an additional eGuardian remote monitoring subscription, remote engineers monitor and assess system performance and provide diagnostics, minimizing the need for on-site interventions.

- Hybrid systems: Combining microfiltration with other technologies, such as UV disinfection or advanced oxidation processes, enhances water purification capabilities.

Advanced Microfiltration Solutions from Aria Filtra

In the quest for high-quality water, microfiltration membranes have emerged as a game-changing technology. With the ability to deliver advanced filtration precision, operational efficiency, and adaptability, Aria Filtra solutions have become indispensable across a variety of industries.

As technology continues to advance, the role of microfiltration in achieving high-quality water and global water security will only grow. From municipal water systems to industrial applications, the versatility and reliability of microfilter membranes ensure they will remain a key component in the future of water filtration.

Contact Us